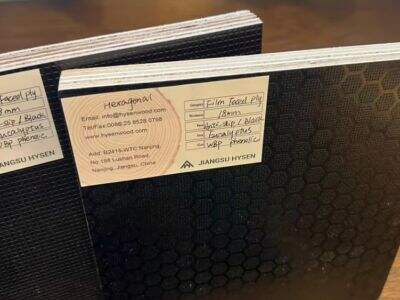

Speciale Bouwprojecten Aangepaste Film Gezicht Plywood

Aangepaste film gezicht plywood is een krachtig en veelzijdig materiaal dat gebruikt kan worden in het bouwproces. Een langdurige, weerbestendige speciale coating. Deze plywood kan nu op een noodzakelijk niveau worden aangepast voor bouwers. Het kan afval voorkomen en maakt bouwprojecten sneller.

Plywood Snijden in Elke Vorm Voor U

Er zijn veel variabelen omdat elk bouwproject anders is en zijn eigen uitdagingen heeft. Het wordt aangepast tot de grootte die nodig is voor uw project, aangepaste film gezicht plywoods. Het kan ook worden behandeld om het bestand te maken of te beschermen tegen verschillende soorten omstandigheden zoals water en glibberige vloeren. Deze aangepaste effectgebied bespaart tijd en geld door perfect te passen, waardoor er minder arbeid ter plaatse nodig is.

Op Maat Gemaakte Plywood

De verkoop van multiplex is een sector die de vraag naar arbeid heeft verlaagd om technologie te laten zorgen voor de meeste aanpassingen. De opties variëren van de grootte, kwaliteit, materialen tot de afwerking die bouwers nodig hebben. Dit is zeer nuttig voor architecten en fabricanten omdat ze weten welke materialen voldoen aan hun eisen, zowel esthetisch als ontwerptechnisch, door adequaat te functioneren. Nog beter, op maat gemaakte multiplexproducten leiden tot een verkorte bouwtijd en zijn duurzamer voor het milieu.

Groene Multiplex van Buildres

Een geavanceerder bouwen dat tegenwoordig te zien is, maakt gebruik van milieuvriendelijke materialen. Het wordt gemaakt van duurzame bronnen terwijl de lijm die wordt gebruikt ook milieuvriendelijk is, waardoor een volledig op maat gemaakte filmgezichts-multiplex mogelijk is. Dit laat bouwers gefocust blijven op hun duurzaamheidsdoelen, terwijl ze tegelijkertijd top-projecten leveren. Groene materialen zijn goed voor het milieu, evenals voor minder vuilnis en lagere kosten.

Voordelen van op maat gemaakte multiplexleveringen

Naast het op maat maken, zijn er veel voordelen verbonden aan custom multiplex. Het heeft een betere kwaliteit wanneer multiplex op maat wordt gemaakt; je kunt steviger en consistentere stukken verkrijgen. Custom bestellingen kunnen ook kosten besparen door korting te bieden en snellere installatietijden mogelijk te maken. Creativiteit en innovatie worden aangemoedigd wanneer custom multiplex een vaste waarde is in het bouwhulpmiddelenpakket.

LEAVE A COMMENT / GELD SPAREN MET CUSTOM MULTIPLEX

Hoewel het wat duurder kan zijn om multiplex op maat te laten maken, bespaar je op de lange termijn geld. Hierdoor bijdraagt het aan minder afval en lagere arbeidskosten doordat het perfect past vanaf de eerste keer. Het bespaart u geld (geen overbestelling met custom maten), het houdt langer stand en heeft op de lange termijn lagere onderhoudskosten ten opzichte van custom hardhout. Deze methode is efficiënt, kosteneffectief en duurzaam in bouwprojecten.

Aangepast Embeeded Type Film Gezicht Multiplex voor Bouwwerk

Tegenwoordig kiezen bouwers voor aangepast film gezicht multiplex voor belangrijke upgrades in hun bouwprojecten. Dit gelakte multiplex is een veelzijdig product met hoge weerstand en biedt gegarandeerde prestaties voor verschillende soorten omgevingen of toepassingen. De industrie gaat meer over naar op maat gemaakte oplossingen die projectvoordelen bieden in het perspectief van de toekomstige trend.

Op Maat Passend voor alle Bouwactiviteiten

Aangezien elk project zijn eigen specifieke eisen heeft, gebruikt men in de derde stap aangepast film gezicht multiplex. Deze oplossingen bestaan uit exacte paneelmaten en coating die specifiek ontworpen zijn om verschillende milieucondities te weerstaan. Aangepast multiplex - In mariene toepassingen en steigersystemen is prestatie essentieel voor de levensduur en esthetiek van een project.

Groothandel Aangepast Multiplex Toen En Nu

Om vraagstukken rond maatwerk in het gebied van multiplexhout te kunnen beantwoorden, hebben grosisten zich aangepast door de nieuwste technologieën in te zetten voor de aanpassing aan hun merk van multiplex. Dit is niet het enige aspect dat aangepast kan worden: klanten kunnen ook kiezen welke kwaliteitsgraad van multiplex, soort kernmateriaal(en) en oppervlak behandeling. Met deze verandering kunnen architecten en bouwvakkers nu materialen selecteren die specifiek zijn toegespitst op hun gewenste ontwerppotentieel terwijl ze tegelijkertijd alle prestatie-eisen tijdens de bouwfase voldoen met verbeterde structurele resultaten.

Duurzaam aangepast multiplex<()>

Als antwoord op de toenemende nadruk op duurzaamheid in de bouw, is maatwerk filmgefaceteert multiplex beschikbaar met milieuvriendelijke opties uit verantwoord beheerde bronnen. Bouwers kunnen zo hun duurzaamheidsdoelen blijven realiseren, terwijl ze ook profiteren van de bouwvoordelen die komen kijken bij het gebruik van duurzame bosproducten en lijmstoffen met lage VOC-uitstoot. Bovendien komt deze groene aanpak niet alleen goed aan bij lokale klanten die milieuvriendelijk zijn ingesteld, maar draagt het ook op een zinvolle manier bij aan wereldwijde natuurbescherming.

Ontdek de voordelen van unieke multiplex leveranciers

Voordelen van maatgeschreven filmbelegde multiplex Superieure Kwaliteitscontrole Besparingen door schaalvoordeel en efficiëntie. Panelen worden op deze manier gebouwd om een hogere sterkte en modulariteit te bieden, waardoor overdadige reparaties of updates in de algemene betrouwbaarheid van het huis voorkomen worden. Daarnaast betekent het loslaten van de kopieer-plakken-benadering het vermijden van overtollige prijzen en leidt tot aanzienlijke besparingen bij op maat gemaakte bestellingen zonder kwaliteitscompromissen.

Balans je budget met Op Maat Gemaakte Multiplex Oplossingen

Hoewel het aanpassen van multiplex lijkt op een extra uitgave, is het op de lange termijn een slimme investering die efficiënt gebruik maakt van bronnen en voorkomt verlies. Maatwerk-multiplex is een van de beste manieren om verspilling te voorkomen door overtollige bestellingen van onderdelen, wat weer arbeidsuren, onnodige kosten verminderd en bovenal het risico verkleint, waardoor u overall geld bespaart. Aangepaste panelen houden langer stand, wat resulteert in lagere kosten door minder onderhoud en vervanging, wat maatwerk-groothandel filmgezicht multiplex maakt tot een belangrijk onderdeel van kosteneffectieve en duurzame praktijken in de bouw.

Conclusie: De Betekenis van Aangepast Filmgezicht Multiplex

De grote aanvaarding van op maat gemaakte filmgefaceteert plywood markeert een belangrijke omwenteling in deze industrie, met technici die de nadruk leggen op nauwkeurigheid, ecologie en technologie. Dit trend naar personalisatie maakt niet alleen projecten efficienter, maar toont ook een toewijding aan kwaliteit, esthetica en het milieu. Terwijl het aantal op maat gemaakte oplossingen groeit, wordt custom plywood nog belangrijker bij het sturen van de bouwsector naar een duurzame en designgerichte toekomst.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

TH

TH

TR

TR

AF

AF

GA

GA

CY

CY