For its strength in water Marine Plywood

Marine plywood is a type of wood material specially made for use in water based environments. Unsurprisingly, the banister material boasts a worthy resilience to harsh weather conditions and culturing fungus for long periods due to its durability. In this article, we are going to discuss the several benefits, technological advancements, protective features and ways of application as well as certain grades and types along with common uses & applications for marine plywood.

Advantages of Marine Plywood

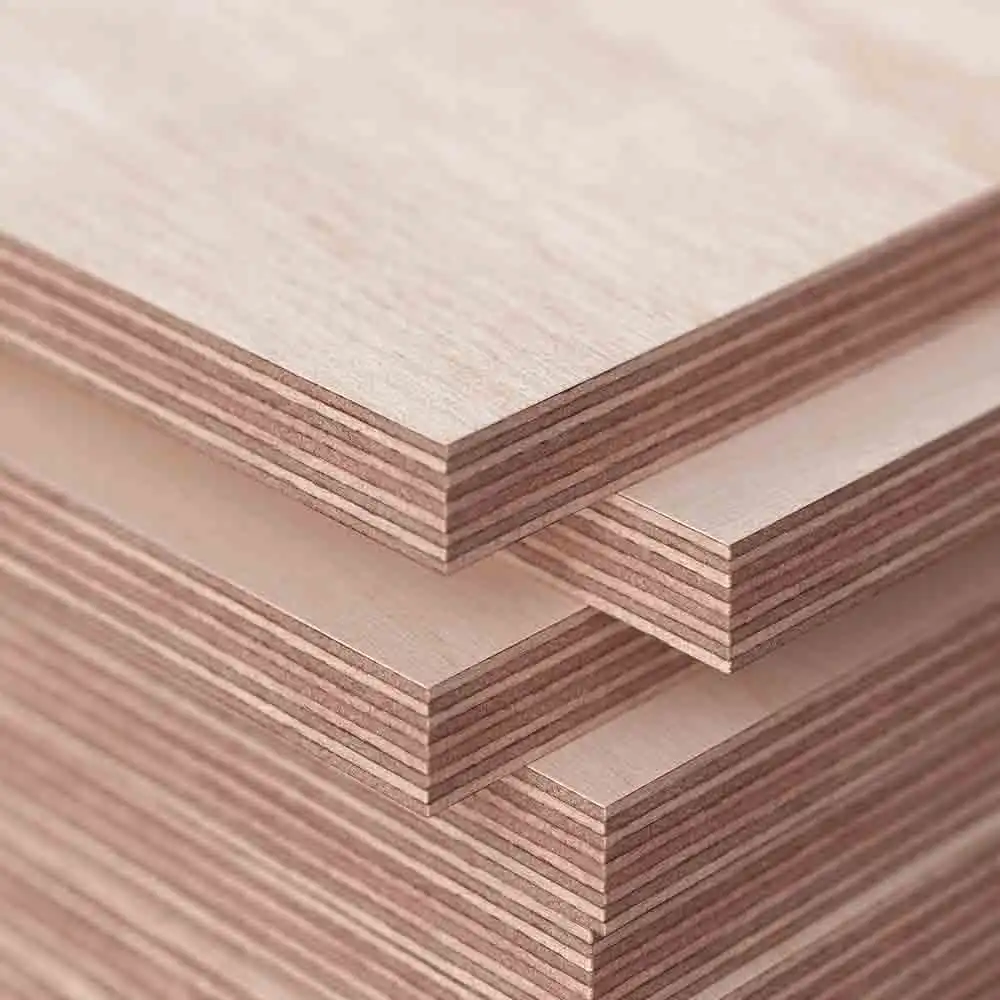

One of the most daunting benefits that marine plywood showers is its brilliance as water and moisture-resistant. Its resistivity allows it to survive rain and other wet environments, which makes this material very suitable for use in many different applications on boats. Besides that, the use of marine plywood will also act as a strong termite/insect repellent and thereby minimize the risk of pest infestation for years to come.

One other benefit that comes with marine grade plywood is the simplicity of use. It is easily cut, sanded or trimmed to a size and shape needed. Marine plywood is constructed using waterproof adhesive to bind together the layers of traditional ply but this also increases its strength and longevity over standard ply.

Marine plywood advances have generated new materials stronger, more versatile and much cheaper than old fashioned lumber products. In cases like this, some marine plywood variations employ artificial adhesives which are resistant to saltwater; thus they may stick together wooden layers more effectively and make the final product fit for a higher number of implementations.

Though, marine plywood is known to be safe for processing it still wise practice precautions. As an example, the sawdust generated while cutting marine plywood can be harmful to us and therefore appropriate protection (read dust mask + goggles) is required. Proper installation is also important so make sure to use the right screws and fasten your plywood accordingly.

In the case of marine plywood, it can serve for a long list of purposes in and out on water. Marine locations for use: subfloor, decking material, cabinetry Marine-grade plywood is also used for other structures outside of the marine industry because this type of wood holds up well in roof decks, outdoor furniture and any area where moisture can be an issue. Marine Plywood can be molded into various configurations, depending on your requirements and how creative you want to get.

Marine Plywood Use and Best Practices

Marine plywood is best to cut with a saw, sand your edges smooth and paint or stain as desired. To be able to efficiently install or use, the wood is left with optimal space which ensures that it dries through completely and at a slow rate. As with any type of shavings, over time it can be prone to wear and tear so following the correct fastening and gluing guidelines for your plywood is essential.

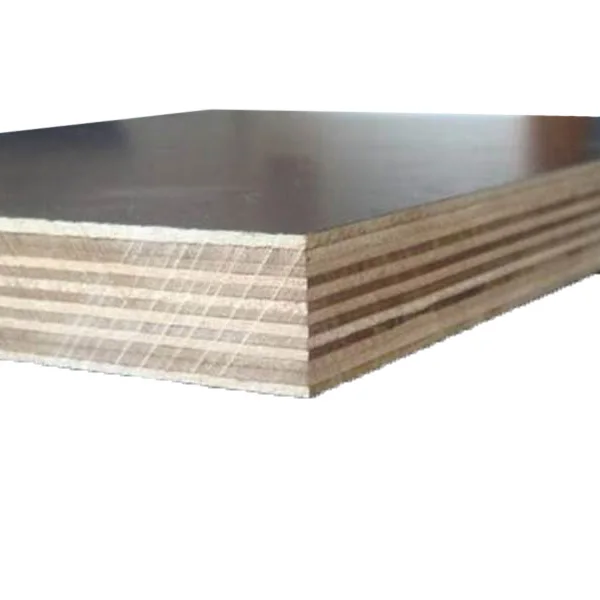

Marine Plywood must have good quality in direct contact with water. A variety of products with quality assurances can be found in marine supply stores. You should look for quality labels, like “BS 1088”, “BS 6566”, and/or the PSSC mark or TUV safety seal to ensure that all plywood meets strict demands. Five to Seven Thin LayersHigh-quality marine plywood is used in 5-7 layers, all glued together with weatherproof glue, and has no defects.

Over last 20 years professional operations constant efforts have 1 4 marine plywooda solid working relationships customers from across the globe, are all eager establish an alliance that will be strategic for the development of markets. We welcome guests to visit office and develop friendships that will aid us in our growth. JIANGSU HYSEN will be your most trusted business partner one stop plywood solution provider!

JIANGSU INTERNATIONAL TRADE CO.,LTD has been operating more than 20 years. are primarily involved in commercial plywood, film backed plywood, MDF/HDF Fancy plywood/MDF, and more. have expanded services include horticulture, 1 4 marine plywoodfurniture other products.

sell premium plywood that 1 4 marine plywoodstrict quality control is compliant with industry standards meet the diverse requirements of clients. plywood is strong and durable to last test of time. company always researching and innovating can provide unique solutions customers. offer custom-designed products and solutions based on the requirements their customers help them solve real-world problems.

business has streamlined logistics 1 4 marine plywoodcan deliver products their destination quickly accurately. also offer flexible delivery options such as customization demand, installment deliveries and on. meet the specific demands our customers. believe in customer satisfaction provide high-quality after-sales support. have a committed team customer service representatives who able assist customers in timely manner solve any customer concerns.